Sewer Repair Done Right!

When sewer problems strike, you shouldn’t have to sacrifice your landscaping to solve them. Our trenchless technology allows us to repair or replace underground sewer lines without tearing up your yard, driveway, or garden. With minimal disruption and long-lasting results, we deliver efficient, environmentally friendly solutions that keep your property intact while fixing what’s hidden beneath it.

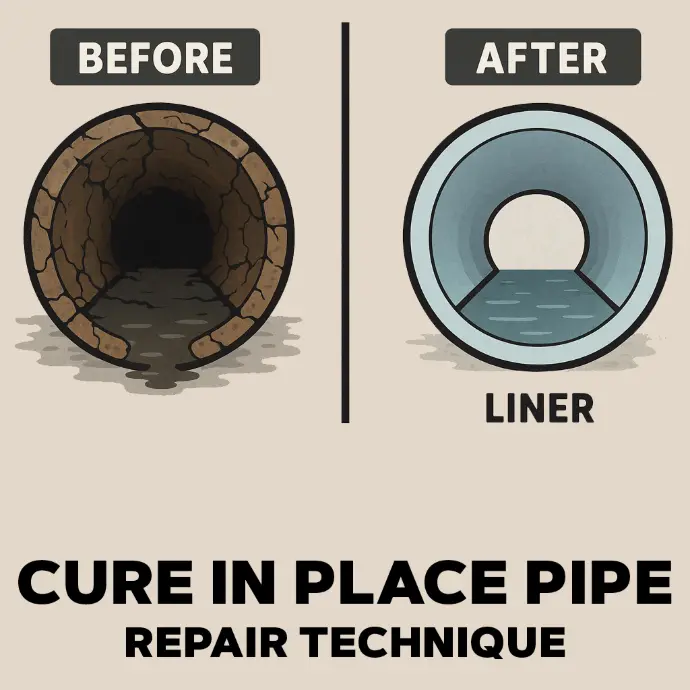

Cured-In-Place Pipe

This trenchless method reinforces the existing pipe by installing a resin-saturated liner, which is then cured in place using UV light to form a new pipe inside the old one. It eliminates the need for excavation, reduces surface disruption, and extends the pipe’s lifespan with minimal downtime and cost compared to traditional replacement methods.

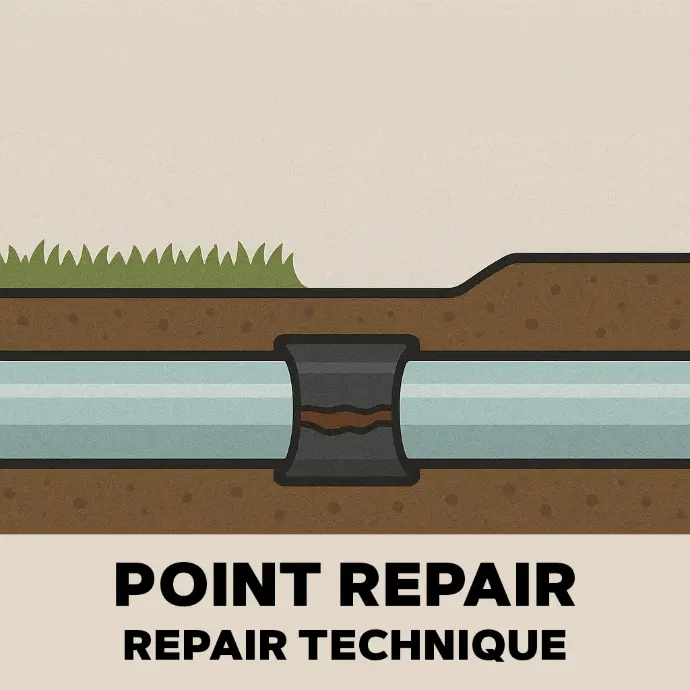

Point Repair

This method identifies and repairs only the damaged sections of a pipe using a localized approach. By targeting specific problem areas with precision, it enables efficient restoration without the need for extensive excavation, minimizing disruption, saving time and costs, and preserving surrounding infrastructure and landscaping.

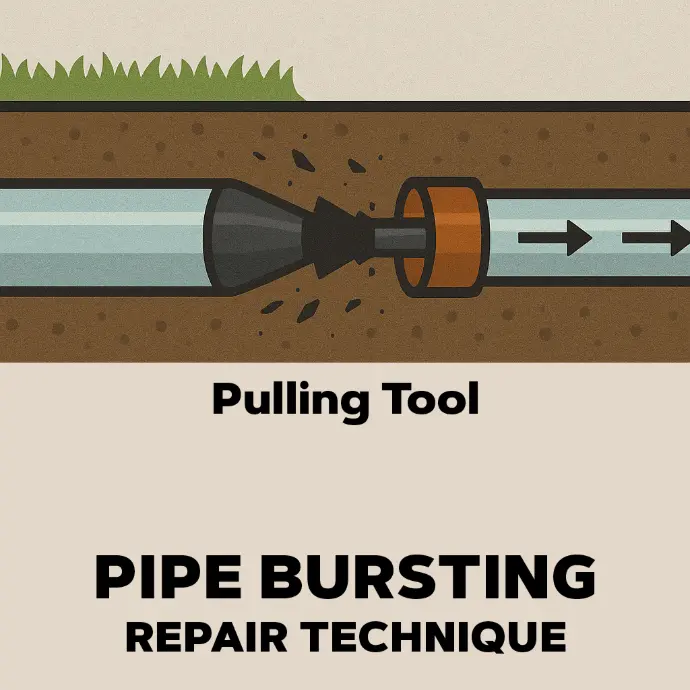

Pipe Bursting

This trenchless technique breaks apart the existing damaged pipe underground, a process called pipe bursting, to create space for installing a new pipe of equal or larger diameter. It eliminates the need for open trench excavation, reduces surface disruption, and allows for capacity upgrades while minimizing environmental and community impact.

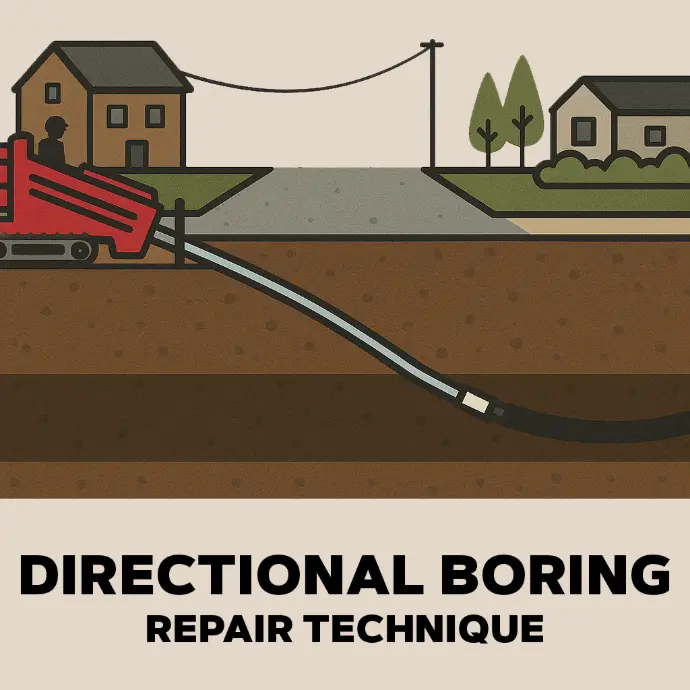

Directional Boring

This trenchless construction method installs service pipes or conduits underground with minimal disruption to the surface. By avoiding traditional excavation, it preserves landscaping, pavement, and infrastructure, ideal for urban areas or sensitive environments where reducing surface impact, noise, and restoration costs is important.

Directional Boring

This trenchless pipe repair method restores and extends the life of existing pipelines. By cleaning the interior and applying multiple protective resin coats, brush coating creates a seamless corrosion-resistant barrier inside the pipe. The result is a durable, long-lasting solution with an expected service life of 30 to 50 years, all with minimal disruption.

WHY CHOOSE GREAT PLAINS TRENCHLESS

25+ Years Local Expertise

Fully Certified and Insured

Typical Job done in one day

Financing options available

FAQS

While pipe lining (such as Cured-In-Place Pipe or CIPP) is an effective trenchless method for repairing and rehabilitating pipes, there are certain situations where it may not be the best solution. Here are some scenarios where pipe lining might not be the ideal choice:

1. Severe Structural Damage:

- When to avoid: If the existing pipe is severely collapsed, crushed, or structurally compromised, pipe lining may not provide adequate reinforcement. Lining is more suitable for pipes with minor to moderate damage, such as cracks or small holes. In cases of significant structural failure, it may be necessary to replace the pipe entirely.

2. Excessive Root Intrusion:

- When to avoid: In pipes where tree roots have invaded extensively, pipe lining might not be effective unless the roots are cleared beforehand. If the roots are widespread or block the pipe entirely, they could interfere with the lining process and affect the long-term performance of the repair.

3. Presence of Severe Corrosion:

- When to avoid: In pipes with extensive internal corrosion, especially in metal pipes, lining might not adhere properly or create a lasting bond. Corroded pipes may need more thorough treatment or replacement rather than just lining over the corrosion.

4. Obstructions in the Pipe:

- When to avoid: If the pipe has significant debris, blockages, or obstructions inside that cannot be effectively cleared, the lining process might not be successful. The pipe needs to be thoroughly cleaned before lining, and excessive obstructions may prevent proper lining installation.

Pipe bursting is an excellent trenchless method for replacing old or damaged pipes, especially when traditional excavation would be costly, disruptive, or impractical. Here are three scenarios where pipe bursting is a particularly good option:

1. Replacement of Old or Deteriorated Pipes

- Example: If you're dealing with old, deteriorated pipes that have become prone to frequent breaks, leaks, or blockages (such as aged clay, cast iron, or asbestos cement pipes), pipe bursting is an ideal choice. It allows for the entire pipeline to be replaced without needing to excavate the full length of the pipe. The new pipe is pulled into place, providing a long-term, durable solution while minimizing surface disruption.

- Why it's good: Pipe bursting effectively replaces the old pipe with a new one, improving the integrity and lifespan of the system while maintaining minimal disturbance to the surrounding area (e.g., roads, landscaping).

2. Replacing Pipes Under Roads or Pavement

- Example: In urban areas where pipelines run beneath busy roads, highways, or parking lots, digging up the surface to replace a pipeline can be a costly and disruptive process. Pipe bursting allows for the replacement of pipes without having to tear up large sections of pavement or concrete.

- Why it's good: By using a directional drill to burst the old pipe and pull a new one in its place, there is minimal disruption to traffic, pedestrian movement, or business activities. It saves on repair costs and traffic delays compared to traditional excavation.

3. Upgrading Pipe Size or Material

- Example: When you need to upgrade the pipe to a larger diameter or more durable material (for example, replacing an old clay pipe with a larger HDPE pipe for higher capacity), pipe bursting is an efficient method. The bursting process allows for both the removal of the old pipe and the installation of a new, larger pipe in the same trenchless operation.

- Why it's good: Pipe bursting can accommodate changes in pipe size while keeping excavation work to a minimum. This is especially beneficial for infrastructure upgrades in areas where access is limited or surface disruption is costly.

- Pipe Point Repair focuses on fixing only a small, localized section of damage within a pipe.

- this is the more cost effective option

- Pipe Lining involves inserting a new lining material throughout the entire length of a pipe

- These processes usually go hand in hand

- Directional drilling is a trenchless construction method that involves drilling at an angle to access underground utilities, such as gas, water, or electrical lines, and fiber optic cables.

- It's also known as horizontal directional drilling (HDD).

- Directional boring can typically reach depths ranging from a few feet to over 100 feet, depending on the project’s requirements. Some advanced rigs can even drill deeper if necessary.