SERVICES WE PROVIDE

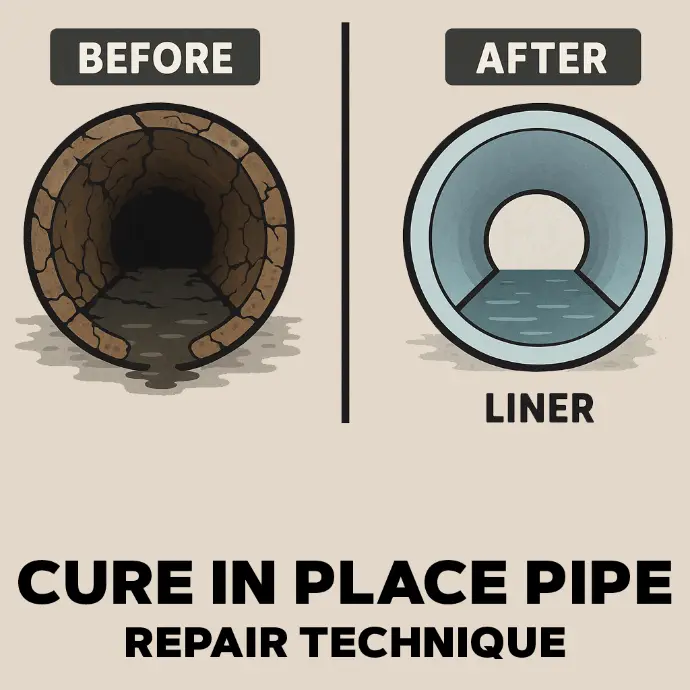

Cured-In-Place Pipe

- Preparation: The damaged pipe is cleaned and prepared, typically using high-pressure water or mechanical tools to remove debris, scale, or corrosion. Cameras are used to inspect and assess the pipe’s current condition.

- Liner insertion: A flexible liner, saturated with a resin mixture (often epoxy or polyester), is inserted into the existing pipe. This liner is usually pulled through the pipe using air or water pressure, or sometimes it’s pushed in from one access point.

- Curing: The liner is then inflated to press against the pipe walls. The resin within the liner is then cured (hardened) using heat or UV light, depending on the method used. This process creates a solid, seamless, and corrosion-resistant pipe within the old pipe.

- Finishing: Once the curing process is complete, the pipe is inspected to ensure proper adhesion and structural integrity. The pipe is then ready to use, and any access points are re-covered.

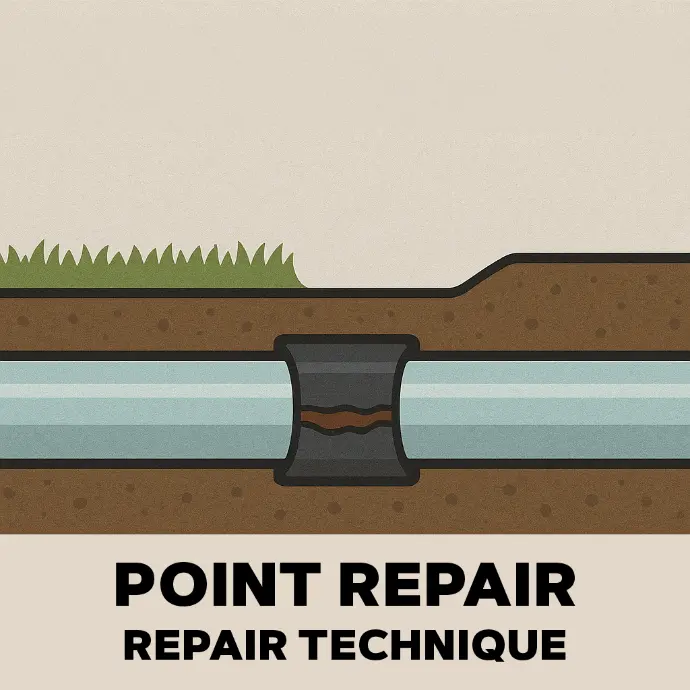

Point Repair

- Inspection and identification: A camera or other inspection tools are used to identify the location and extent of the damage in the pipe. This step helps pinpoint the exact area that needs repair.

- Preparation: The damaged area is cleaned, often with high-pressure water or mechanical methods, to remove debris and ensure good adhesion for the repair material.

- Installation of the repair: Depending on the method, a variety of materials can be used for the repair. One common option is a reinforced patch, which is applied over the damaged section. The patch is often made from fiberglass or a resin-saturated material that hardens once it’s in place.

- Curing and finishing: The repair material is left to cure (harden), forming a durable, sealed barrier that restores the strength and functionality of the pipe. A final inspection ensures the repair is secure and the pipe is fully functional.

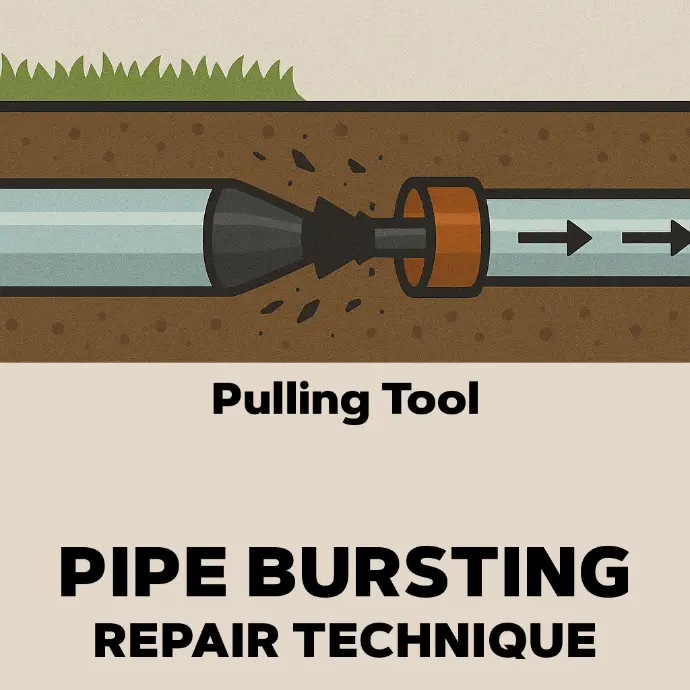

Pipe Bursting

- Initial setup: A bursting head (a cone-shaped or cylindrical tool) is inserted into the old pipe through a small access point at each end of the pipeline.

- Breaking the old pipe: The bursting head is pulled through the old pipe, using hydraulic or pneumatic force, breaking it apart as it moves forward. The fragments of the old pipe are pushed outward into the surrounding soil.

- New pipe installation: As the bursting head moves through, it pulls a new pipe into place behind it. The new pipe is usually made of a more durable material (like HDPE – high-density polyethylene), which is resistant to corrosion and cracking.

- Completion: Once in place, the new pipe is inspected for alignment and integrity before being connected to the existing system. The access pits are then backfilled, and the surface is restored. Finally, pressure and leak tests are conducted to ensure the system is functional before it is put into service.

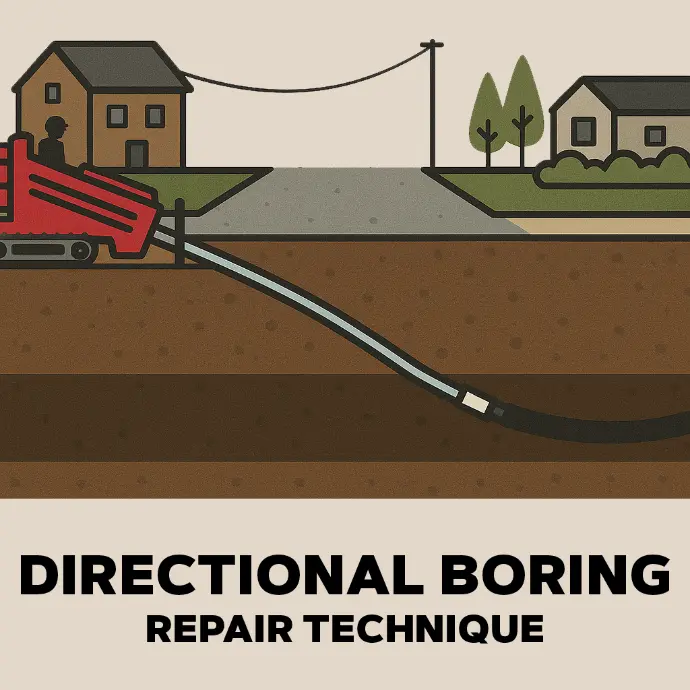

Directional Boring

- Pilot hole drilling: The process begins by drilling a small pilot hole from one side of the area to the other, following a carefully planned path. A specialized drilling rig is used to steer the drill bit precisely along the desired trajectory.

- Reaming: Once the pilot hole is drilled, the hole is gradually enlarged (reamed) to the desired size to accommodate the pipe. This is typically done in stages, using larger drill bits to widen the hole.

- Pipe insertion: After the hole is fully prepared, the new pipe (often made of high-density polyethylene or steel) is pulled through the bore. The pipe is connected to a "back reamer," which pulls the pipe through the hole while ensuring the pipe is properly aligned.

- Completion: The installation is complete once the pipe has been fully pulled into place, and the rig is removed from the site.

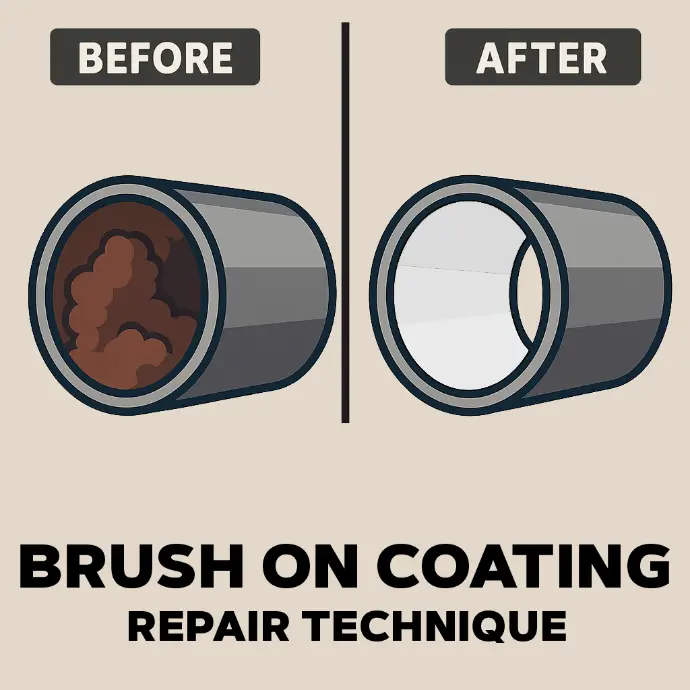

Brush Coating

Epoxy brush coating for sewer pipes is a protective system designed to enhance the durability and corrosion resistance of underground sewer systems. This coating is typically a two-part epoxy resin that, once mixed, creates a strong, waterproof barrier that adheres well to the surface of pipes.

- Corrosion Resistance: Epoxy coatings protect pipes from a wide range of corrosive substances, extending their lifespan significantly.

- Waterproofing: The coating creates a seamless, moisture-resistant layer that prevents leaks and infiltration.

- Ease of Application: The brush-on application method allows for easy access to hard-to-reach areas of the pipe.

- Durability: Once cured, epoxy coatings provide a hard, resilient finish that can withstand physical wear and chemical attacks.

- Customization: The coating can be tinted or modified for specific applications, ensuring compatibility with various sewer materials and conditions.